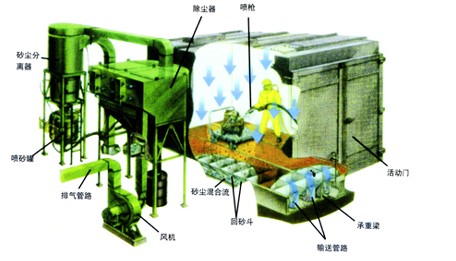

The main characteristics of the environmental protection type wind blasting room is to adopt the honeycomb sand suction floor technology, adopt the pneumatic conveying principle, use the pneumatic power to recover the sand material, and then send it to the sand dust separator through the pipeline for automatic sand dust separation. The sorted useful sand material will automatically fall into the main machine of the sandblasting machine (sandblasting pressure tank) and enter the recycling use; the sorted broken sand material, paint skin, The useless sundries such as oxide skin and dust will automatically enter the dust collector for filtering and dedusting.

As the honeycomb sand suction floor adopts pneumatic conveying, it is unnecessary to use traditional machinery to transport the belt, winch, scraper pulley, chain, bucket elevator and other traditional rotating moving machinery in the sand blasting chamber, which avoids the abrasion of the transport machinery, bearings and motors caused by sand and dust during the sand transport and lifting process, and avoids heavy maintenance work. And its installation does not need a deep pit (or even a pit), which shortens the construction period and saves the cost of capital construction; while the traditional sandblasting room generally needs to excavate a 2.5-3.5m deep pit according to the size of sandblasting room.

As the air inlets for sand material recovery and dust recovery in the wind blast chamber are all arranged under the honeycomb sand suction floor, the air flow and dust are always from top to bottom, and the dust is always pressed on the lower part of the blast chamber, the dust concentration in the space of more than 0.5m in the blast chamber is very low, the visibility is very high, and the working environment is good; however, due to the structural reasons, the traditional blast chamber dedusts dust. The mouth must be arranged at the top or side of the shot peening chamber, and the dust flow direction is from bottom to top or horizontal. Therefore, the dust content in the shot peening chamber is always high, the visibility is low, and the working environment is poor during the sand blasting operation.

The whole cycle of the wind blast chamber is fully pneumatic and automatic, and the equipment fully meets the requirements of environmental protection during operation.

Based on the introduction of foreign advanced sand absorption floor technology, our company has developed and designed environmental friendly wind blast chamber, which can be designed and manufactured according to the product characteristics and sand blasting requirements of customers. The wind suction sand floor sand blasting chamber uses the wind power of the fan as the power, sucks the abrasive through the return pipe to the cyclone separator for separation, and then enters the sand blasting system for recycling. It has the following advantages:

A. the screw and belt conveyor, bucket elevator and underground engineering of the conventional sand blasting chamber's sand conveying circulation system are omitted, and the construction cost of foundation is saved and the engineering cost is greatly saved.

B. high abrasive recovery, easy to clean and replace abrasive. Can transport any sand material such as steel sand;

C. The main electrical components are imported products, with stable performance, safety and reliability, long service life and simple maintenance;

D. there is high visibility in the sandblasting chamber, and the chamber is naturally winded to save energy consumption;

Contact:Ms. Chen

Contact:Ms. Chen